(303) 420-8242 | 7333 W. Jefferson Ave., Suite 235, Lakewood, CO 80235 USA

(303) 420-8242 | 7333 W. Jefferson Ave., Suite 235, Lakewood, CO 80235 USA

C&IH’s exposure simulation testing facility provides a unique approach to simulate past, present, and future exposure scenarios.

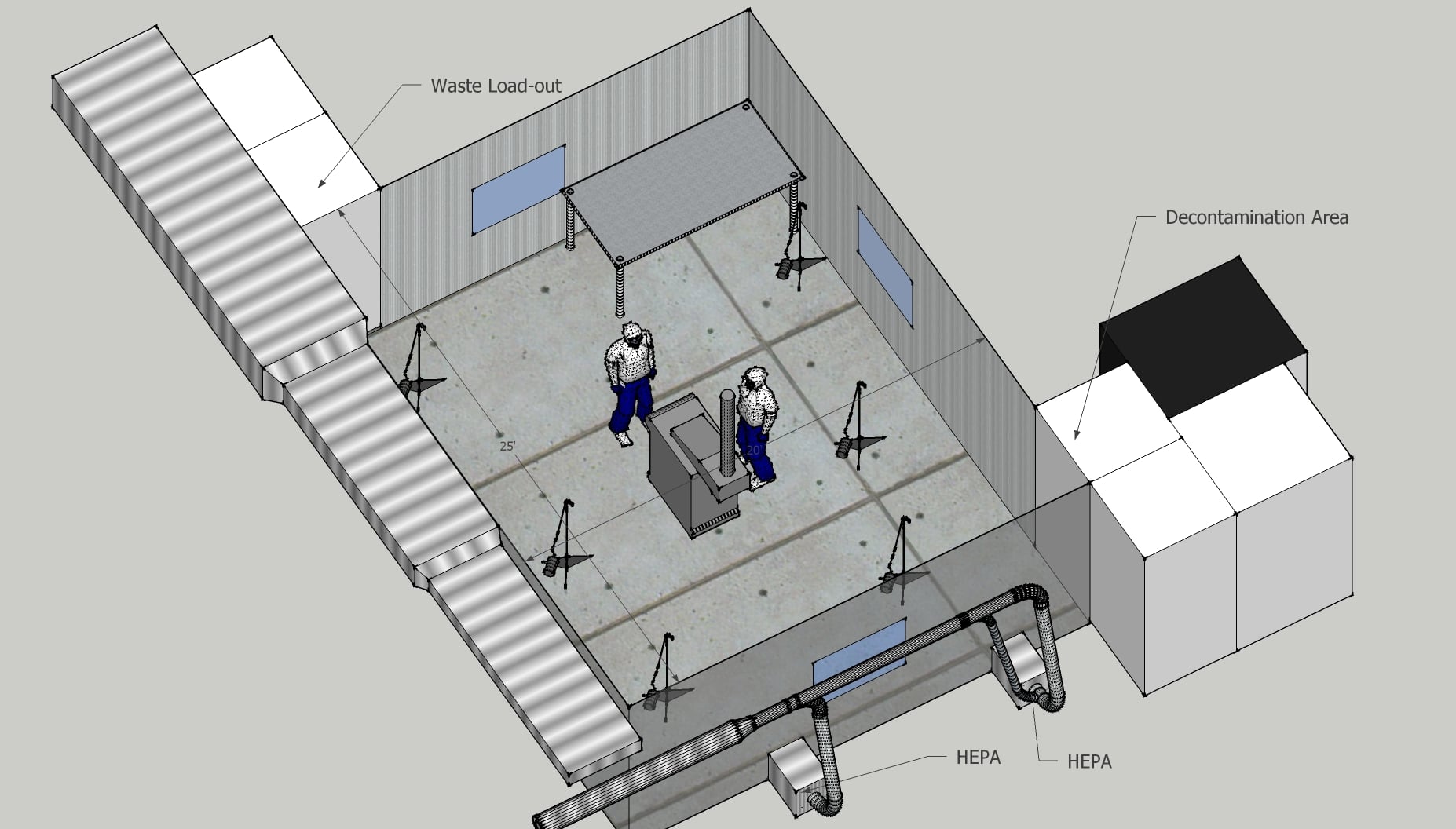

Our facility includes fully modifiable testing chambers that are utilized to conduct both workplace contaminant simulations and to perform bench-scale and full-scale product exposure testing.

Designed by C&IH’s team of certified industrial hygienists and ventilation engineers, the state-of-the-art simulation testing facility enables historical or present work practices to be created or recreated in a controlled environment. C&IH collaborates with clients to design and customize testing chambers that meet the unique requirements of each project. This process allows for real-world parameters, and various work practice scenarios, to be incorporated into exposure simulations.

The adaptability that comes with designing chambers specific to project needs enables in-depth study of real-time contaminant dispersion associated with specific work practices and product exposures. An adjustable chamber design also facilitates C&IH’s ability for conducting simulations to validate historical exposure monitoring data or data generated by exposure modeling.

Simulation testing chambers are designed to meet Client needs on a project-by-project basis

Chambers can be constructed from a variety of materials

Air flow rates into and out of the chamber are adjustable, including ventilation locations and air changes per hour (ACH)

C&IH’s simulation facility can be utilized to perform exposure assessments involving particles, gasses, fumes, mists, and vapors. Exposure simulations are conducted by a C&IH team of laboratory-experienced professionals with advanced degrees and educational backgrounds in analytical chemistry, biochemistry, toxicology, epidemiology, and minerology, as well as certified industrial hygienists (CIH), board-certified toxicologists (DABT), and ventilation engineering professionals (PE). The technical resources of our staff allow C&IH to perform exposure assessments and risk characterizations for a wide variety of industry-specific processes and product-specific exposures. This includes emerging technologies with unknown health risks, such as the printing of molded materials and manufacturing with nanoparticles.

C&IH has conducted a broad assortment of additional exposure simulations. Please contact us to discuss the unique requirements of your project.